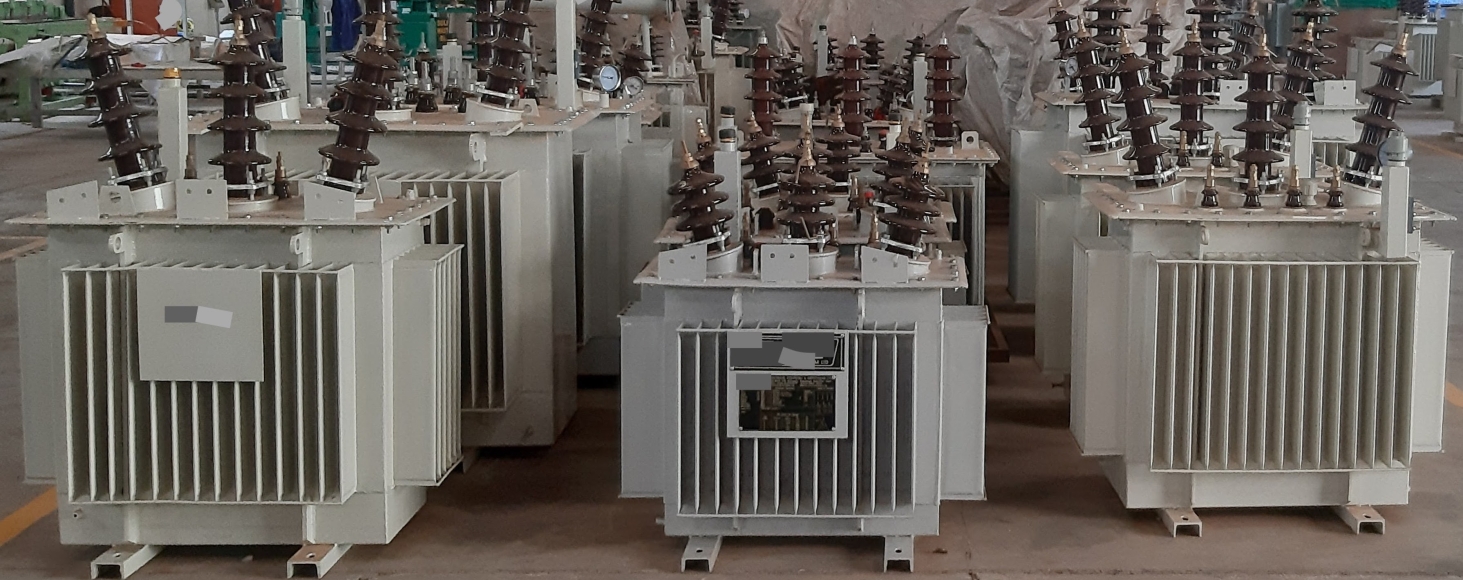

In the past 15 years, Ugandan manufacturers have increased investments and capacity to make products used in electricity generation, transmission, and distribution networks. These include electric cables, poles (wooden and concrete), distribution panels, transformers, cement, and steel, among others.

However, due to past policies, the Electricity Supply Industry (ESI) has yet to begin purchasing economic quantities of these locally manufactured products. This has resulted in the industry's return on investment remaining sub-optimal.

The current situation presents a significant problem with a long history, affecting supply and demand. Manufacturers are grappling with low capacity utilization, leading to poor cost competitiveness and weak business performance. On the other hand, the ESI has been spending significant resources (>$200m per annum) on procuring imported transformers, electric cables, and other equipment.

If the ESI can sustainably increase its purchases of transformers and electric cables from local manufacturers, the results would be enhanced business performance, jobs, economic growth, and a positive impact on the balance of trade. It would further reduce the effect of forex exposure on electricity tariff determination, effectively lowering the price of electricity to the end consumers while encouraging increased investment in Uganda’s manufacturing sector.